Mold-Tek Packaging (MTPL) is the leader in rigid plastic packaging in India. The company is involved in the manufacturing of injection molded containers for lubes, paints, food and other products.

MTPL has seven processing plants and three stock points spread across India to ensure faster supplies. As a pioneer and innovator of pail packaging in India – Mold-Tek has introduced spouts and In-Mold spout concepts for the paint and lube pails.

With in-house manufacturing capability in place, it is not dependant on imports.

Mold Tek Plastics is the leader in manufacturing of plastic packaging products including pails. It specializes in both standard and made-to-order packaging solutions for leading brands of paints, lubricants, pharmaceuticals, cosmetics, FMCGs, etc.

Mold Tek is the only one-stop-shop in India to produce injection and blow moulded container pails, PET bottles and jars under one roof. It believes that innovation is the key to better products and more cost-effective solutions. The company constantly updates and uses the latest mould and tool design concepts, but still continues to rely on its years of experience in this field.

The company’s in-house tool room is its USP. Equipped with 3D CNC Mikron (Swiss-make) machines and supported by the latest CAD/CAM facilities, its tool room enables it to design and manufacture moulds in fraction of the time taken by any other commercial tool room. This also translates into reduction of mould costs by as much as 50%, shorter lead-time, boosting output and achieving a rapid product development.

Product Range

Variety of containers for pharma and cosmetic products including 60, 100,170 and 200ml bottles.

Child resistant caps and bottles.

Flip-top tablet packs/tube type pharma packs, closures and caps.

Blow-molded shampoo and medicine packs for Himalaya Drug Company, Pantene shampoo bottles for P&G.

Injection-molded, 750ml to 50 litre plastic conipails (with inj-mould or external spouts), for packing lubes, greases, chemicals, paints, bulk drugs, inks, synthetic adhesives, etc.

35 and 50 litre bulk packs for chemicals, agro and other applications

Plant locations

The company has 11 plants located across India with their head office being in Hyderabad. The company started as packaging provider for lubricant companies followed by paint companies. In paints, they started with Berger and are now amongst the biggest suppliers to Asian paints. Most of their plants are located closer to the target client locations.

The company is setting up further 3 plants for Grasim in Panipat, Cheyyar and Mahad. 2 of these plants will go live in FY24 and third will go live in FY25.

The company has also ventured into Sultanpur plant which is expected to go live in FY25.

The company has significant expansion plans of around 250-280 crores of which 130-150 crores are already invested and the rest will be done in FY24-FY25.

Revenue by industry

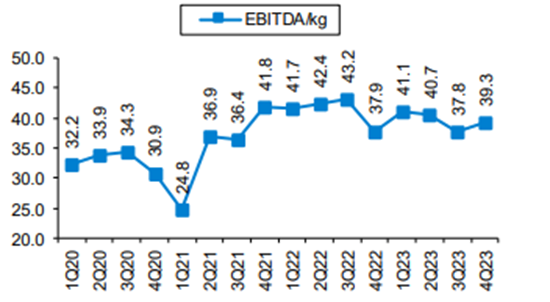

EBITDA per kg – Long term average

Capacity and volume:

| Particulars | 2023 |

| Capacity – Tons | 45290 |

| Volume – Tons | 34014 |

| Utilization | 75% |

| Revenue – crore | 731 |

| Revenue/ kg | 215 |

| EBITDA | 136 |

| EBITDA/ kg | 40 |

| Total Revenue | 731 |

| Paints | 358 |

| Lubes | 183 |

| Food and FMCG | 190 |

Clients List

Economics of the business

| Capex – Crores | 130 |

| Capacity added (Tons) | 10,000 |

| Revenue – Crores | 215 |

| EBITDA – Crores | 40 |

| Interest – Crores | 10 |

| Depreciation – Crores | 9 |

| EBIT – Crores | 31 |

| Capital Employed – Crores | 184 |

| ROCE | 17% |

| Capex/ ton in Rs | 1,30,000 |

Innovation

Mold-Tek Packaging limited is an iconic Indian packaging firm, established by Mr. Laxman Rao in 1986. They drive the Indian plastic packaging space through exemplary designs, excellent aesthetics, enhanced re-usability and 100% recyclable concepts. Today, they are market leaders and knowledge experts of Indian injection molding industry with 8 ISO certified units, revenue over Rs 550 crores and market capitalization over Rs.1000 crores.

Mold-Tek’s contributions are widely acknowledged and appreciated by all its valued customers like Asian Paints, Castrol, HUL, P&G, Mondelez, Wipro etc., owing to near perfect quality standards and everchanging designs/innovations to match their needs for over 30 years. Beginning with paint and lubricant manufacturers in the early 90’s, Mold-Tek now solves packaging problems for the extremely demanding pharmaceutical, food and FMCG sectors as well.

Mold-Tek was recognized as “The best SME of 2013” by ICICI-CNBC, TV18 & CRISIL in their Emerging India Awards, 2013 among 150000 participating companies. They even received the MOST TECH SAVVY SME of the year award for making own robots in-house. Mold-Tek also won the Dun & Bradstreet-RBL Bank SME Business Excellence Award in 2017, in Mid-Corporate segment for Excellence in Plastic & Product category.

Driving the Rigid Plastic packaging industry through innovations

The narrative of Mold-Tek is one of constant innovation – of repeatedly introducing game-changers in the field of plastic packaging even before competition has caught up with the previous innovation. Mold-Tek’s flare to identify customer problems and develop solutions gives them a sustainable edge.

In the early 90’s, Mold-Tek was the first company to introduce plastic pails, replacing metal tins for paints. Mold-Tek started this innovation with Asian Paints, which ignited a disruptive revolution in paint packaging in India. Plastic pails are transport-worthy, durable and provided re-use value for consumers. Their biggest problems of adulteration and tampering were 100% arrested with these new designs, while improving aesthetics and branding.

Few years later, Mold-Tek launched a new concept to expand its pail revolution – “Flexi spout pails” for lubricant oils and other liquids. Today, all lubricant companies have completely shifted to plastic as the product provided innumerable benefits.

“We drove many such innovations in the mould and plastic packaging industry in the country. Our position as market leader is a result of a plethora of competitive advantages”, states J Laxman Rao, CMD – Mold-Tek Packaging. Mr. Rao has over 30 years of work experience. Under his leadership, Mold-Tek went for public issue in 1993 and is listed on BSE & NSE.

Technical excellence through Backward Integration

While Mold-Tek is an injection molding firm, its USP arrives out of backward integration into itsown mold making tool room. Mold-Tek’s R&D and close control on quality and productivity stems from extensive knowledge of how plastic granules are converted into containers, using these in-house manufactured complex molds.

Mold-Tek’s operations and tool room is headed by Mr. Subbramanyam – Technical expert and knowledge leader in injection molding sector. The state-of-the-art tool room is equipped with high-end CNC machines and precision tools to manufacture multi-cavity hot runner molds and even develop highly complex ROBOTS, used in making IML containers. This competency enables Mold-Tek to lead change by introducing spouted pails, tamper-evidence features and leak-proof containers in multifarious shapes. All of Mold-Tek’s paint and lubricant packs serve as industry benchmarks and received international acclaim for innovative designs.

IML containers for 100% recyclability– World’s most advanced decoration

In 2010-11, Mold-Tek introduced In-Mold Label (IML) Decoration in India, considered the best decoration technique across the world. IML gives HD photographic imagery and glossy decoration on packs with no human contact to enable high brand visibility and hygiene. It is a robotic labeling method wherein the pre-printed PP label is placed inside the mold by robots and then, plastic flows

fusing the label with the container. This makes the end product homogeneous (PP label container) and hence, 100% recyclable.

When Mold-Tek launched IML, it was regarded as expensive and futuristic. But they quickly identified three major needs – economic labels, durable molds and very fast robots – to make IML viable especially in a cost conscious country like India. The company immediately started a world-class printing facility for making labels and to die-cut them perfectly to fit the container. This eliminated the need to import IML labels – reducing cost and time dependency. Not stopping here, Mold-Tek’s engineers even developed extremely fast robots at a fraction of the cost of imported robots.

IML containers are 100% recyclable as both the label as well as the container are made of the same material. Hence, there is no need for label separation which any other form of decoration technique struggles with thus rendering the plastic only reusable but not recyclable. IML containers can be completely ground to plastic granules which can be reused for making nonfood packaging.

‘MAKE IN INDIA’ – In-house development of super-fast IML robots

Though there are Billion dollar packaging companies globally, Mold-Tek is the ONLY packaging company in the World to design and develop robots in-house. This is another game-changer which enabled Mold-Tek to take control of the entire manufacturing process of IML, ensuring higher quality standards and reliable delivery commitments to its clients. Today, Mold-Tek designed and produced over 40 robots giving them a long standing edge to deliver unmatched service levels.

Mold-Tek also introduced Square shaped packs for edible oil and ghee packaging with IML decoration, which are certified as the only available option to 100% arrest adulteration and counterfeiting widely prevalent in these industries. All IML packs are manufactured in clean room facilities to remain as hands-free hygienic products. IML decorated thin wall containers are suitable for harsh storage conditions, deep freezing, microwave and are used for food and FMCG products world over.

Advantages of IML are surplus including barcode printing, QR coding, outstanding quality, hygiene and suitability for D2F (Direct to fill) operations, improved barrier properties that helps extend the shelf life of the filled goods, and better heat, moisture and chemical resistance of labels compared to other types of decoration. Mold-Tek is considered as the go-to company for IML packs for Mondelez, P&G, Unilever, Nestle, ITC, Amul and more than 100 other clients.

Customized Packaging Solutions

MOLD-TEK encourages new frontiers in packaging and continuously works towards matching client’s requirements. While working with MNCs, Mold-Tek encourages design-based problem solving sessions. Mold-Tek’s 10-member team creative design studio interacts with marketing/purchase/packaging teams of clients to understand their marketing brief, packaging vision, advertisement strategy, production line constraints etc. in order to come up with options that are compatible to manufacturing.

We drove many innovations in the mould and plastic packaging industry in the country. Our position as market leader is a result of a plethora of competitive advantages.

Then the design studio develops a ‘virtual’ product in 3D rendered form just after conceptualization of the packaging. This enables clients to visualize exactly how the product will look in the package, on the shelf, and in the store. Post this, prototypes are developed for physical analysis. Once the design is frozen, the concept-to-commercial development time also gets drastically reduced as Mold-Tek develops own molds and robots. This go-to-market or launch time for MNCs with Mold-Tek reduces to just 2 to 3 months.

Dispensing pumps – agility to cater to India’s needs even during pandemic

At a time when the fear of COVID was at its peak, Mr. Laxman was finalizing plans to set up fully automatic dispensing pump manufacturing to cater to the sudden surge in demand for sanitizer pumps in India. The company has invested approximately 16 crores in the last six months to set up a fully automatic line with 100% online quality checks. Main application of these pumps would be for hand-wash, sanitizers, body soaps, lotions and shampoos.

I3aintenance, QC and assembly has been brought together. The improved pump mechanism (new TM/ Patent design) would ensure more no. of strokes and leak proofness. With India quickly latching on to online shopping, models are e-commerce compliant too with E-clip to ensure no transit damages happen.

The future is Smart Packaging

Packaging shields the product, keeps it safe, improves shelf life, and creates the first impression for the brand/product. People link superior packaging to superior product. With advent of QR codes & smart packaging, inventory tracking and product experience are linked to packaging. Mold-Tek is gearing up its production and printing capabilities to meet this demand. They invested in a futuristic new technology to print unique QR codes on each pack to track it through distribution, retailing and even post-sale usage. This will remove the problem of counterfeiting, brand duplication while providing superb traceability and consumer experience.

Mold-Tek today serves many sectors beyond paints and lubricants – including edible oils, food products, ice creams, cosmetics and pharmaceuticals – testifying to the company’s growing reputation for innovation, quality and sustained delivery systems. They are rapidly expanding geographically and in product portfolio to cater to more and more applications.

In the last 5 years alone, Mold-Tek has invested more than INR150-200 Cr, which is equivalent to all the investments in the previous 25 years combined.

This year, MOLD-TEK has issued shares and warrants (a novel financial instrument) to raise Rs. 73 crores to further expand their product range and capacity. They have plans to start a new plant in the North and expand capacities of their 2 plants, which are dedicated to Asian-Paints. The future looks promising as their growth strategy is well diversified.

Mold-Tek with its years of technical excellence in injection molding, state of the art infrastructure, excellent leadership and dynamic second generation entrepreneurs with an inclination for innovation is ready to cater to the rapidly changing packaging needs of Indian consumers

Other important points:

The Co. undertook a huge capex of ₹125 Cr. during FY23. This includes –

– Addition of 2600 MTPA capacity at Daman, Vizag, Hyderabad and Kanpur units

– Doubling IML label printing capacity to 4.5 Cr. labels per month by adding additional Rotogravure and Flexo machines (Rs. 17 Cr)

– Increasing Tool room capacity from 4 molds per month to 8 molds per month (Rs. 5 Cr)

– Setting up a second plant at Daman with robotic In-mold labeling (IML) facilities to produce Food & FMCG IML containers. This plant will also add IBM products later. The Co. is adding a capacity of 4700 MTPA at Sultanpur and Daman Units. The total capex allocated for the Sultanpur and Daman projects are Rs. 50 Cr and Rs. 30 Cr respectively.

Injection Blow Moulded (IBM) Project

The Sultanpur plant (Unit-10) for IBM, Pharma & Food products is under active construction and expected to start production by October 2022. The pilot IBM project at the Co.’s Unit-1 is slated to start trial production by October 2022.

Acquisition of Land

The Co. has acquired 2.7 acres of land in Uttar Pradesh for greenfield expansion, next to Berger Paints plants which is expected to be commercialized by FY23.

Issue of Shares under Rights Issue

The Co. has issued ~18.7 lakh rights equity shares at an exercise price of ₹184 upon conversion of detachable warrants into equity shares.

Issue of Shares under Qualified Institutional Placement (QIP)

During the quarter ended 31st December, 2021, the Co. has issued 14,00,000 equity shares at an issue price of Rs. 740 per equity share (including premium of Rs. 735 per equity share), aggregating to an amount of ~Rs. 100 Crores through Qualified Institutional Placement.

In-house Capabilities

Mold-Tek has set up in house robot manufacturing, mold and label manufacturing and die-cutting machines to enable quick production of IML containers. It has an in-house tool room and is the only company in India to have completely integrated facilities ranging from label making, mold adaptations to making in-house robots.

Strategic Focus

The Co. is focusing on leveraging its grip in Injection Molding (Mold design, IML, productivity) and providing low weight options to customers in Pharma, FMCG & Cosmetics. Furthermore, it intends to launch 3-4 concept products every year, establish new plants in Kanpur and Hyderabad and double capacities in Vizag & Mysore. Moreover, it plans on entering new industries like Seeds, Cheese, Fertilizers, Sweets etc.

Promoter group and Shareholding:

| 2023 | |

| CMD – Promoter director | J Lakshmana Rao |

| Deputy MD – Promoter director | A subrahmanyam |

| Deputy MD – Promoter director | P Venkateswara Rao |

| Whole time director | Shrinivas Madireddy |

| Non-Executive Independent director | 6 |

| CFO | A Seshu Kumari |

| Statutory auditor | M anandam and co |

| Cost auditor | Praturi and Sriram |

The promoter is a technocrat with MBA from IIMB. He has been the founder along with A Subrahmanyam and P Venkateswara Rao. CFO of the company A sheshu kumari is his sister and A Subrahmanyam is his brother-in-law.

Shareholding:

Promoter group: 33%

FIIs: 16%

DIIs: 19%

Public: 32%